Integrated Power and Energy Measurement Technology

October 1, 2025

Precise energy monitoring for maximum efficiency

Beckhoff offers an integrated solution for real-time energy monitoring that records electrical parameters such as voltage, current, and power directly within the EtherCAT I/O system. This transparency reduces machine downtime, prevents component oversizing, and enables a rapid response to grid faults such as phase failures. Deviations from normal operating conditions, including increased power consumption due to bearing wear, are detected early to allow for timely interventions.

The system portfolio, designed for ISO 50001-compliant energy management, includes EtherCAT Terminals, measuring transformers, and a software library for monitoring with TwinCAT. It supports preventive maintenance, increases production efficiency, and offers scalable flexibility – from simple energy monitoring to comprehensive network and load analysis.

Future-proof energy data acquisition with Beckhoff

In addition to basic monitoring, Beckhoff provides detailed analyses of key grid parameters, including frequency, active power, reactive power, and apparent power. Seamless integration into control systems eliminates the need for external measurement technology, as all measurements are carried out directly within the EtherCAT I/O system. Real-time processing enables instant detection of grid fluctuations and anomalies, allowing for immediate corrective action directly in the control system. This not only improves fault management, but also enables predictive maintenance by detecting early signs of machine wear – minimizing downtime in the process.

Key benefits:

- IoT-enabled solutions: maximum transparency for energy consumption

- highly scalable portfolio: equally suitable for simple and sophisticated applications

- complete solution from a single source: perfectly coordinated hardware, software, and accessories

- reduced cabling work: thanks to distributed power measurement with EL344x Terminals

- flexibility: suitable for various voltage ranges and industries.

EtherCAT Terminals

Versatile solutions for power measurement and preliminary evaluation

From grid monitoring and process control to high-end power monitoring, energy management in machinery and the energy industry calls for adaptable solutions. Beckhoff’s power and energy measurement terminals are engineered for a wide range of applications and optimized to meet diverse requirements. The scalable portfolio includes:

- fully pluggable measurement systems for effortless installation

- no need for current transformer configuration thanks to electronic nameplates

- threshold monitoring for voltage, frequency, and phase

- grid and power analyses with up to 600 measured values

- high-resolution grid monitoring with oversampling

- distributed power measurement for accurate real-time data

- integration into medium-voltage grids via voltage transformers using a 110 V AC interface

Measuring transformers

Reliable and scalable power sensor technology

As a system provider, Beckhoff integrates powerful sensors directly into the PC-based control with its SCT current transformers – from measured value acquisition through to cloud-based data transmission. Users can choose from a range of scalable designs and performance classes to ensure an ideal fit for any application. The extensive SCT portfolio includes:

- cost-effective transformer sets for building technology

- standard industrial transformers for machine building

- high-precision solutions for test benches and applications with the highest accuracy requirements

TwinCAT

Precise evaluation of current and voltage data

The TwinCAT Power Monitoring function is a powerful PLC library for evaluating raw current and voltage data. It allows users to calculate RMS values for current, voltage, and power – available as instantaneous, average, maximum, or minimum values. What’s more, the library offers comprehensive grid analysis functions, including frequency determination, frequency spectrum analysis, and harmonic evaluation, as well as the calculation of total harmonic distortion (THD) for evaluating the grid quality.

The function blocks support both 1-phase and 3-phase systems. The TE1300 TwinCAT 3 Scope View Professional and TF6420 TwinCAT 3 Database Server products are suitable for visualization and long-term storage of the measurement data.

The TF6735 TwinCAT 3 IoT Communicator App offers a simple and flexible solution for remote monitoring and analysis of TwinCAT process data – anytime, anywhere.

Additional power measurement components

Distributed power management

Measuring current and voltage at multiple locations is essential in many applications, e.g. to accommodate distributed loads or address spatial constraints. Nevertheless, precise power calculations can be ensured by synchronizing and processing the measurement values in real time.

A highly accurate synchronization process ensures reliable power data, even when current and voltage readings are taken separately. This includes the calculation of apparent power, active power, and reactive power, enabling a detailed analysis of energy consumption and grid quality. The technology not only allows for flexible placement of the measuring points, but also ensures that the recorded values are synchronized with high accuracy. As a result, power assessment quality remains consistent, regardless of the physical distance between measurement points.

Power Quality Factor

Beckhoff has developed the Power Quality Factor (PQF) to simplify the evaluation of current performance data as much as possible for users. This guide value provides a single numerical indicator of voltage quality within a system’s environment, eliminating the need to separately analyze frequency, voltage, THD/harmonics, and symmetry. For example, if a machine error occurs and the PQF simultaneously drops to zero, it suggests that the issue is likely due to a change in the power supply rather than the machine itself. This approach not only helps to identify symptoms and effects more quickly, but also speeds up root cause analysis. At the same time, a falling PQF can be used as an early warning system.

Safety in the control cabinet

Standard I/O system signal voltages are typically ≤ 48 V. In power measurement applications, however, signal voltages often reach ≥ 230 V, requiring additional safety measures to prevent personal injury. This is why Beckhoff offers several options for identifying power measurement terminals.

- Identification via an additional I/O station using an EtherCAT Coupler. Voltages < 48 V and < 690 V are separated.

- Identification via the EL9080 separation terminal with signal color.

- Identification via the BZ3201 slide-in label cover featuring a ‘HIGH VOLTAGE’ warning.

More Information

Related Story

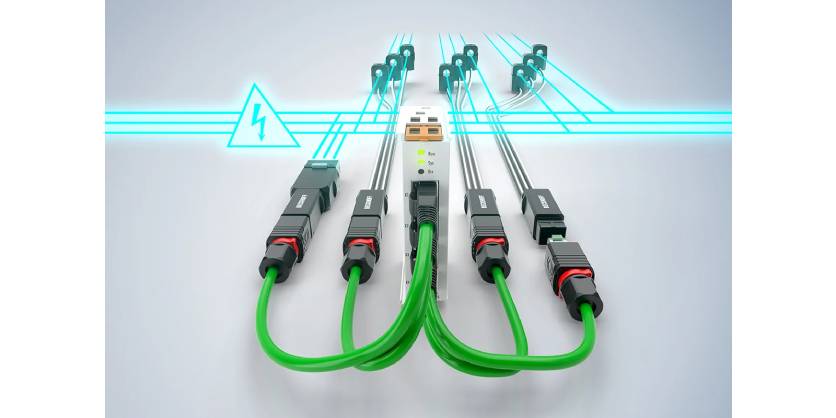

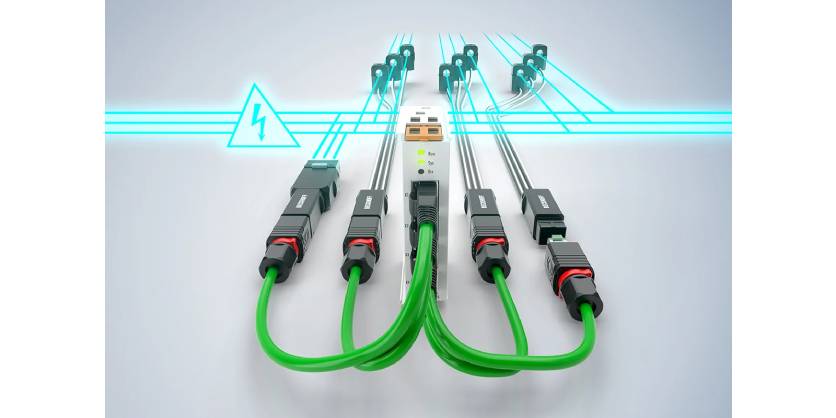

Beckhoff Future-Proofs Hybrid Connectors in Industrial Cable Offering

Beckhoff’s proven hybrid connectors, part of the company’s One Cable Automation (OCA) solution, are receiving a major update to better support distributed automation well into the future. Beyond the design advantages of consistent modularization with a uniform data core, these connectors now comply with the upcoming IEC 61076-2-118 standard, enabling a seamless transition in advance of the rollout.