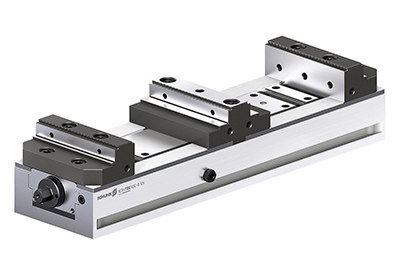

SCHUNK Growing Double-Acting Clamping Vises Series

February 5, 2019

After just one year on the market, SCHUNK is systematically expanding its series of powerful KONTEC KSC-D double clamping vises.

As of now, the light and flat double clamping vises with the most in demand jaw width of 125 mm are available in seven body lengths: 320 mm, 390 mm, 460 mm, 530 mm, 600 mm, 670 mm, and 740 mm. In size 80, one length is standardized: 300 mm SCHUNK KONTEC KSC-D double clamping vises are specially designed for demanding continuous operation in automated machine tools with workpiece storages.

An induction-hardened base body, long jaw guides, fitted slides, case-hardened chuck jaws, and a fully encapsulated drive ensure a consistently high precision, maximum wear resistance, and minimum cleaning effort. Completely nickel-plated, the vise is perfectly protected against corrosion for continuous use in pallet systems or on tombstones.

Easy loading due to third-hand function

By means of a convenient thirdhand function, two workpieces can be inserted next to each other, fixed, and securely clamped together. Due to the trapezoidal threads, high clamping forces can be achieved with little manual effort.

As a part of the SCHUNK modular system for highly efficient workpiece clamping, the clamping force blocks offer further advantages: The clamping pins of the quick-change pallet system SCHUNK VERO-S without adapter plate can be directly screwed into the base body of the vise. The clamping force blocks can also be fitted with a wide variety of chuck jaws from the SCHUNK standard chuck jaw range.