New PROFINET Bus Interfaces From Festo

December 14, 2020

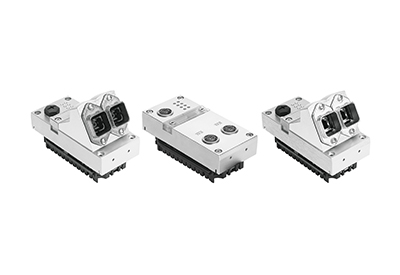

Festo has recently introduced a new generation of PROFINET bus interfaces for its CPX automation platform. These new FB44 and FB45 interfaces add four key features based on the latest PROFINET controllers and software, including S2 System Redundancy that provides redundant protection to keep processes running in the event of a CPU error.

In addition, these new industrial Ethernet interfaces provide three other notable equipment features: MRPD (Media Redundancy for Planned Duplication) for uninterrupted ring redundancy, voltage monitoring and NTP (Network Time Protocol) time synchronisation. PROFINET is the most widely used Industrial Ethernet protocol worldwide and also Festo’s biggest seller.

There’s more: With these PROFINET bus interfaces, assets and diagnostics as well as process and parameter data can be visualised via a web page, thus reducing engineering costs. The incorporated IT services help to reduce downtime while the integrated concept and valve diagnostics increase machine availability. The high protection rating to IP67 enables direct machine mounting.

With S2 system redundancy, when there is a CPU error, the process continues to run via the redundantly installed central processor. The switchover takes place automatically. S2 system redundancy can be combined with either MRPD or MRD redundancy and its ring topology. (MRPD and MRP prevent malfunctions or loss of communication caused by a cable or device defect.)

The FB44 and FB45 interfaces also opens up opportunities for the CPX automation platform with the PROFINET bus interfaces in the process industry when used with Siemens PCS, S7 controllers and ABB control systems.

During the development process, Festo made one-to-one compatibility between the new nodes and their predecessors a priority. For example, this allows users to replace old FB34 bus interfaces on a one-to-one basis with new FB44s without having to make any configuration changes. The existing data cables and connectors can continue to be used and even the old PROFINET .GSD files are retained. All that is needed to change the bus interfaces is to remove the old nodes, fit the new ones into the CPX platform or a valve terminal with a bus interface to accommodate this PROFINET upgrade.

For more information, visit www.festo.com.