FISCHER Announces Expansion of Repair Service Offerings for 3rd Party Spindels

May 23, 2024

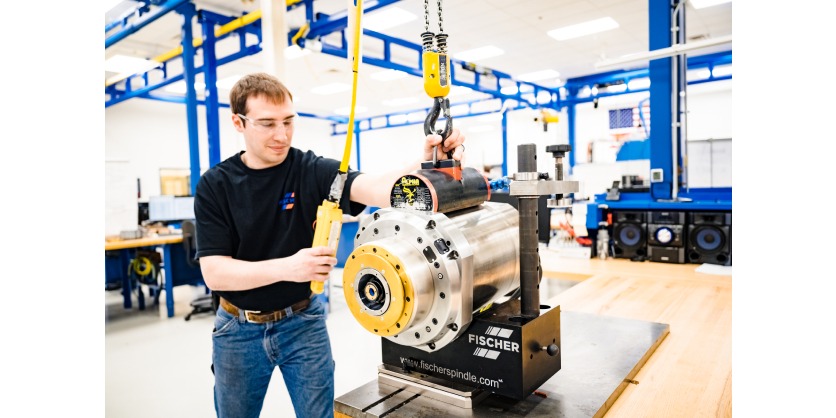

Company to bring its machining, testing and assembly talents to work on non-Fischer spindles

Under the theme of “Technology Leader with Perfect Rotation,” FISCHER USA, Inc. will display its branded spindles plus offer a new service at IMTS 2024, Booth 237470, in Chicago, September 9-14. With 85 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company will formally introduce the expansion of its repair services and exchange programs for non-FISCHER spindle brands to the North American market.

As Vice President Doug Kranz notes, “We have invested substantially in recent years in new machines, processes and, our most important asset, our people, to support our growth. Today, we can now offer our full battery of services to work on non-FISCHER spindles most commonly found on high performance, high precision machines.” Kranz further says that the company has curated a special niche in the machine tool market in North America, focusing on more complicated spindles that other repair shops may tend to avoid. “We pride ourselves in taking on the spindles many others stray away from.”

For the immediate future, Kranz explains FISCHER USA will target Kessler spindles, commonly found on large format SW machines, typically used in the automotive market for high-production work. In addition, the company is focusing on Makino spindles for several lines of that builder’s machines, specifically MAG3. “Currently, MAG3 machines are well known to have spindles that only Makino repairs. We have been asked to repair them for several years now and have decided to make a major commitment to this type of work. As a result, FISCHER has invested in a pool of spindles and we will repair them, stock them and roll out our exchange program for MAG3 users Q1 2025,” says Kranz.

The MAG3 machines are used primarily in the aerospace sector, where FISCHER has a long history and strong presence directly with the aerospace manufacturers and their first and second tier suppliers.

Finally, the company will target a repair and exchange program for Voumard multi-spindle, ID high-speed grinding machines. The company will maintain a pool of those spindles in stock, ready for immediate exchange with fast delivery and a competitive price point.

In regard to pricing, Doug Kranz observes, “Our price points will be lower than the OEM’s in most cases, while we maintain the very high-quality standards FISCHER has long established in the American market.”

At the booth, FISCHER will also display its impressive array of branded spindles and head assemblies for milling, drilling and grinding operations.

Visit them at IMTS 2024 in the North building, Level 3, Booth 237470.

More Information

FISCHER USA, INC.

3715 Blue River Avenue

Racine, WI 53405

Related Story

FISCHER to Feature New Milling Head Spindle Combination at IMTS 2022

Under the theme of “Technology Leader with Perfect Rotation,” FISCHER will showcase its D27 milling head paired with their newest technology for high-volume material removal in their MFW-2714/20 HSK-100 at IMTS 2022, Booth 237470, in Chicago, September 12-17. With 80 years of experience in high-performance machine tool spindle design, in-house manufacturing and best-in-class repair services, the company will present this new design, a combination milling head-milling spindle that provides maximum stability and precision for aerospace and other 5-axis machining operations.