Doig Corporation Launches First Off-The-Shelf Palletizing Solution in North America, Powered by OnRobot’s D:PLOY

May 14, 2025

Doig Corporation Launches First Off-The-Shelf Palletizing Solution in North America, Powered by OnRobot’s D:PLOY

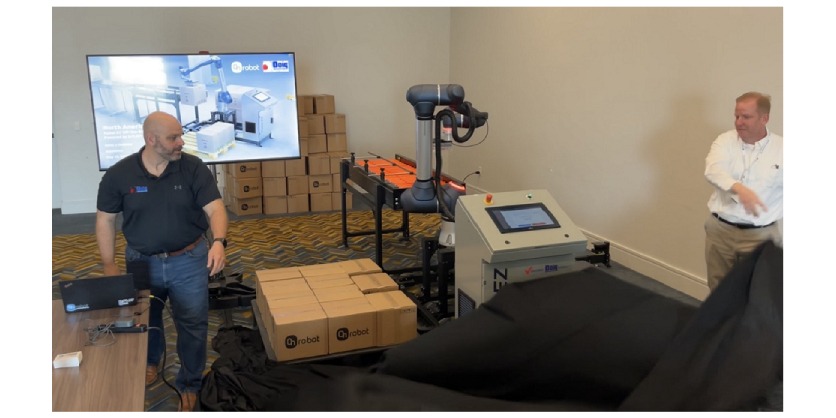

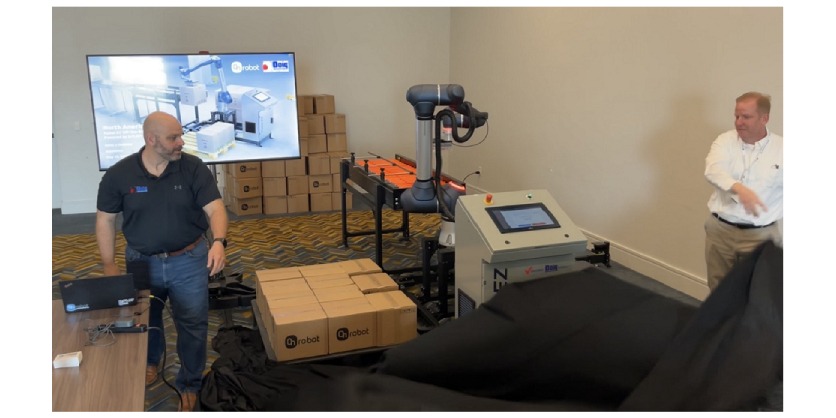

At Automate 2025, Doig Corporation debuted Pallet EZ – the first true Off-The-Shelf palletizing solution in North America. Developed in collaboration with OnRobot and powered by the groundbreaking D:PLOY platform, Pallet EZ redefines what’s possible for manufacturers looking to automate without complexity.

Unlike traditional automation systems that require weeks of integration and specialized expertise, Doig’s Pallet EZ is ready to install and deploy the same day. It allows manufacturers to be up and running within hours, and adjust to changing production needs in minutes, without programming knowledge or external support.

For small and mid-sized manufacturers struggling with labor shortages, repetitive manual tasks, and growing production demands, Pallet EZ offers a new path to automation: one that’s fast, flexible, and future-proof.

“This launch marks the arrival of a completely new category of automation – one designed for the real-world needs of manufacturers today,” said Eric Kraus, Director of Sales and Automation at Doig Corporation. “With Pallet EZ, our customers don’t have to choose between affordability and innovation. They get both, along with simplicity, safety, and long-term scalability.”

Powered by OnRobot’s D:PLOY, the solution eliminates traditional integration hurdles. Applications can be deployed and re-deployed in minutes, empowering users to handle new workpieces, adjust pallet layouts, and evolve with changing production demands, all in-house, without coding.

By removing the need for complex programming and providing full pricing transparency, Doig’s Off-The-Shelf Solution reduces both risk and cost, enabling manufacturers to see return on investment faster and scale automation on their own terms.

Doig Corporation is a Preferred Partner for OnRobot’s D:PLOY platform, bringing a shared mission to lower automation barriers and help more manufacturers succeed.

About OnRobot

OnRobot is a global leader in collaborative applications, making industrial automation accessible, flexible, and cost-effective for manufacturers of all sizes, and we’ve been doing so since 2018. With headquarters in Odense, Denmark, other offices around the world, and a network of more than 700 distribution and integration partners, we’re on a mission to eliminate complexity and deliver collaborative automation that works – straight out of the box.

At the heart of our offerings is a growing portfolio of Off-The-Shelf Solutions powered by D:PLOY, the industry’s first automated application deployment platform. These pre-fabricated solutions enable same-day installation, fast changeovers, and require no programming expertise, allowing manufacturers to automate high-mix tasks like palletizing and machine tending in just a few hours, and taking control of their operations.

Complementing these solutions, OnRobot provides a comprehensive range of Plug & Produce tools – including grippers, vision systems, sensors, and screwdrivers – all designed to work seamlessly across leading robot brands through our unified ‘One System, Zero Complexity’ platform.

Whether it’s palletizing, CNC machine tending, packaging, transferring, sanding, or screwdriving, we help businesses take control of their automation journey – with solutions designed to scale, adapt, and deliver measurable results.

Related Story

OnRobot’s VGP30 Gripper Strengthens the Hardware Behind Off-The-Shelf Solutions

OnRobot was founded in 2018 with the mission of breaking down barriers to automation so manufacturers of all sizes can reap these benefits. They have a wide product portfolio of hardware and software solutions for collaborative applications that cover major industries, all hallmarked with easy integration, quick changeover capabilities, and compatibility with most major cobot brands. The latest addition in their product portfolio is the VGP30, their highest payload vacuum gripper designed for enhanced collaboration automation.