Cognex Launches 3D-A1000 Item Detection System

December 11, 2020

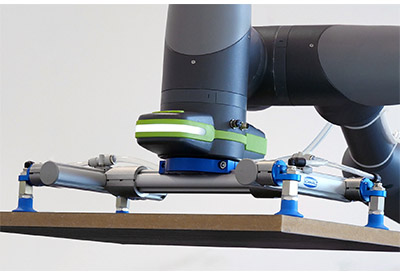

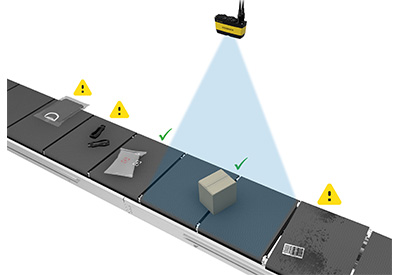

In early August of 2020, Cognex Corporation introduced the 3D-A1000 Item Detection System. A motion-capable smart camera, the 3D-A1000 can identify the presence or absence of objects with unmatched accuracy on all types of sorters traveling at production line speeds. This product release extends the 3D-A1000 platform into new applications for helping retail and logistics customers reduce delivery errors, improve throughput, and increase fulfillment efficiency.

“As consumers increasingly expect reliable and fast delivery, retailers need to ensure the right products get to the right customers on time, every time, said Carl Gerst, Cognex Senior Vice President. “The 3D-A1000 Item Detection System is a powerful, turnkey solution for detailed inspections in sorting that hasn’t been available until now.”

Unlike conventional methods, the 3D-A1000 uses patented 3D Symbolic Light technology to freeze motion with a single image. The system gathers precise 3D and 2D information without the need for an encoder, allowing detection of low contrast objects while avoiding tray hygiene issues. Embedded processing then uses Cognex vision tools to provide detailed inspections of trays and objects.

The 3D-A1000 is factory calibrated and ready for system integration immediately. As opposed to traditional systems that can take a skilled engineer three to six hours to install and calibrate, the 3D-A1000 can be installed in less than 15 minutes.