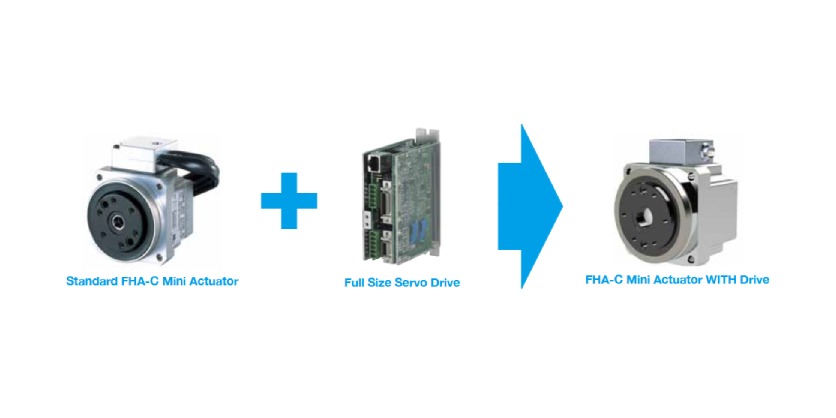

Harmonic Drive Actuators with Integrated Drive Technology

February 11, 2025

Discover the future of motion control. This video explores how integrated drive technology (IDT) from Harmonic Drive is revolutionizing the precision motion control industry. Watch as they demonstrate key features of our advanced actuators and how your industrial automation projects can benefit from them.

Packed with features, IDT actuators are your last stop for rotary motion control.

Key highlights of Harmonic Drive actuators with integrated drive technology:

- Zero backlash strain wave gear: Experience high precision motion with Zero Backlash from the original manufacturers of the strain wave gear

- Advanced servo drive built in: A complete servo drive under the cover offers real time feedback, control loop tuning, advanced trajectory modes including position, velocity, and torque control, and much more functionality

- Simple cabling: IDT actuators only need one cable which dramatically simplifies wire management, especially in manufacturing automation and robotics projects where cable management can be particularly challenging

- Packed with sensors: Dual absolute encoders eliminate the need for battery backups within a single output revolution, on board temperature sensor and motor phase current monitoring helps ensure your motor never operates above its limits

- Simple setup: Get going quickly with our custom software where you can test drive your actuators, modify parameters, tune control loops, update firmware, and much more

- Industry 4.0 ready: Speed up your smart factory initiatives by connecting all of your sensors, equipment, and integrated actuators to a single communication bus

More Information

Related Story

How to Build Better Robotics with Integrated Actuators

Integrated actuators are transforming the way robotics are designed, offering compact, highly efficient solutions that improve performance and reduce complexity. This detailed article by Harmonic Drive delves into the benefits of integrated actuators, explaining how they combine a motor, gearhead, and feedback system into a single unit to enhance precision, reliability, and space savings.

Harmonic Drive explores key design considerations, such as selecting the right actuator for the application, optimizing for torque and speed, and addressing thermal management. It also highlights how integrated actuators streamline the development process by eliminating the need for separate component sourcing and assembly, making them ideal for robotic applications across industries like manufacturing, healthcare, and autonomous systems.