Guide to Mechatronics – Part 7: Challenges and Problem-Solving in Mechatronics

January 27, 2025

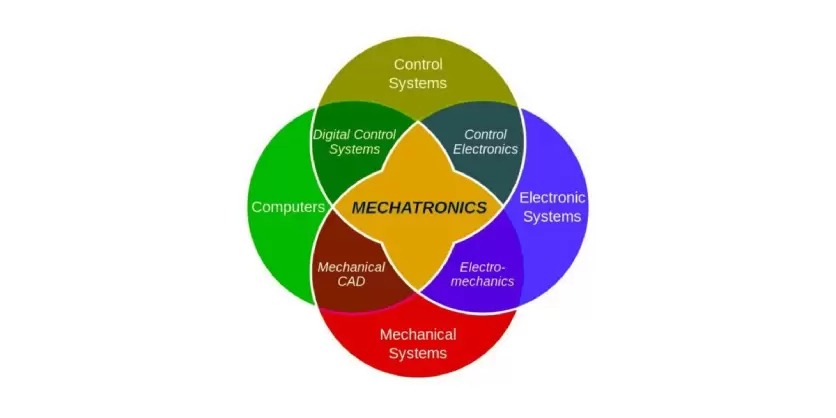

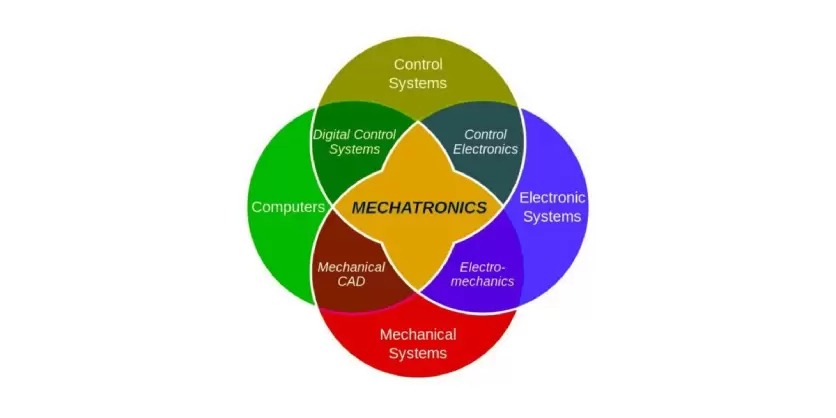

The field of mechatronics, while innovative and dynamic, comes with its own technical and integration challenges. These challenges often stem from the interdisciplinary nature of mechatronic systems and the complexity of blending mechanical, electronic, and computational elements into a cohesive unit.

Technical Challenges

- Complexity in Design: The multifaceted nature of mechatronic systems often leads to increased complexity in design. Balancing the mechanical, electronic, and software aspects while meeting performance specifications can be challenging.

- Miniaturization and Material Selection: As devices become smaller and more integrated, selecting the right materials and components that can operate reliably at reduced scales becomes critical.

- Power Management: Efficiently managing power in systems that combine electronics and mechanics is a persistent challenge, particularly in portable and energy-efficient devices.

- Heat Dissipation: Managing the heat generated by electronic components and friction in mechanical parts is essential to maintain system performance and prevent failure.

Integration Challenges

- Interdisciplinary Coordination: Achieving seamless integration requires close coordination among specialists from different engineering disciplines, each with its language, tools, and methodologies.

- System Compatibility: Ensuring that different components and subsystems are compatible in terms of communication protocols, power requirements, and physical dimensions is a significant hurdle.

- Real-Time Data Processing and Control: In applications requiring real-time responses, integrating data processing and control mechanisms to function within the necessary time constraints can be challenging.

- Testing and Validation: Comprehensive testing of mechatronic systems is complex due to the interaction of various subsystems. Ensuring that the system operates reliably under different conditions is essential.

Problem-Solving Approaches

- Systems Engineering Approach: Adopting a holistic project view, focusing on system integration from the beginning rather than treating each component separately.

- Iterative Design and Prototyping: Using iterative processes and rapid prototyping can help identify and address issues early in the design phase.

- Simulation and Modeling: Advanced software tools for simulation and modeling can predict system behavior and interactions, allowing for refinements before physical implementation.

- Cross-Disciplinary Teams: Forming teams with diverse expertise can foster innovative solutions and ensure that all aspects of the system are considered from multiple perspectives.

Addressing these challenges requires a combination of technical expertise, creative problem-solving, and collaborative effort. As the field of mechatronics continues to evolve, finding solutions to these challenges is key to unlocking the full potential of mechatronic systems in various applications.

Solutions and Best Practices for Overcoming Mechatronics Challenges

To effectively address the challenges in mechatronics, it is essential to employ a combination of strategic planning, best practices, and innovative problem-solving approaches. These solutions aim to streamline the development process, enhance system performance, and ensure reliability.

Strategic Planning and Project Management:

- Early Integration Planning: Begin the integration process in the early stages of design to anticipate and address potential compatibility issues between different subsystems.

- Risk Assessment and Management: Implement thorough risk assessment strategies to identify potential problems early and develop contingency plans.

Design and Development Best Practices:

- Modular Design: Adopt a modular approach to simplify testing and troubleshooting and facilitate easier upgrades and maintenance.

- Design for Manufacturability and Maintainability: Ensure that designs are not only technically feasible but also practical for manufacturing and maintenance.

- Use of Standardized Components: Utilize industry-standard components to improve compatibility and reduce complexity.

Advanced Tools and Technologies:

- State-of-the-Art Simulation Tools: Leverage advanced simulation software to model and test various aspects of the system under different scenarios.

- Rapid Prototyping: Use techniques like 3D printing to quickly create and test prototypes, allowing for faster iterations and refinement.

Interdisciplinary Collaboration and Communication:

- Cross-functional Teams: Foster collaboration between engineering disciplines to encourage holistic problem-solving and innovation.

- Regular Communication and Reviews: Maintain open lines of communication among team members and conduct regular project reviews to ensure alignment and address issues promptly.

Testing and Validation:

- Comprehensive Testing Protocols: Develop robust testing procedures that cover not just individual components but also their interaction within the system.

- Real-world Testing Environments: Test systems in conditions that closely mimic their intended operational environment.

Continuous Learning and Adaptation: - Up-to-date Industry Knowledge: Stay informed about the latest technological advancements, materials, and processes relevant to mechatronics.

- Feedback Loops and Learning from Failures: Implement feedback mechanisms to learn from operational data and past failures, continuously improving system design and performance.

Implementing these solutions and best practices requires a proactive and iterative approach, focusing on system integration, effective communication, and leveraging advanced tools and technologies. By doing so, engineers and designers can navigate the complexities of mechatronic systems, paving the way for innovative and reliable solutions in this ever-evolving field.

This article is original content created and posted by Electromate. Please do not re-post this content without prior approval from Electromate.

Related Stories

A Guide to Mechatronics – Part 1: Introduction & Fundamentals

A Guide to Mechatronics – Part 2: Composition of a Mechatronic Subsystem

A Guide to Mechatronics – Part 3: Strategies for Integrating Mechatronic Subsystems

Guide to Mechatronics – Part 4: Software & Programming

Guide to Mechatronics – Part 5: Tools & Languages in Mechatronics Software Development

Guide to Mechatronics – Part 6: Applications of Mechatronic Subsystems