SCHUNK and 3M Can Show You How to Start Automating Material Removal Processes

June 3, 2021

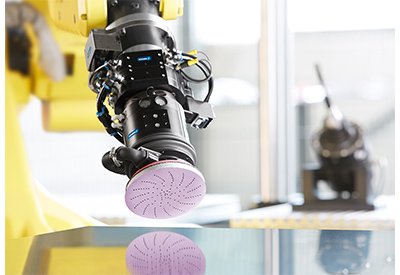

Robotic material removal offers some advantages towards manual machining. It is less expensive, more precise, reproducible, and can be implemented unmanned around the clock. But how can the process be successfully changed over? To which factors do users have to pay attention when automating their sanding processes, and how must they interact to achieve the highest possible degree of productivity?

SCHUNK, a specialist for gripping systems and clamping technology and 3M, a major manufacturer of industrial abrasives, will answers such questions in a free online seminar on June 15, and June 16, 2021 . They will show several case studies demonstrating how to get started with robotic material removal, highlight best practices for success, and illustrate how common challenges can be streamlined with the right abrasives and tools. The online seminar is aimed at beginners and people with limited experience with robots, system integrators and users. In addition to theoretical principles and practical applications, this interactive online format also offers the opportunity to discuss specific issues and to exchange ideas with other participants.

Register HERE.