From Small Lab to Global Additive Manufacturing Powerhouse

January 28, 2025

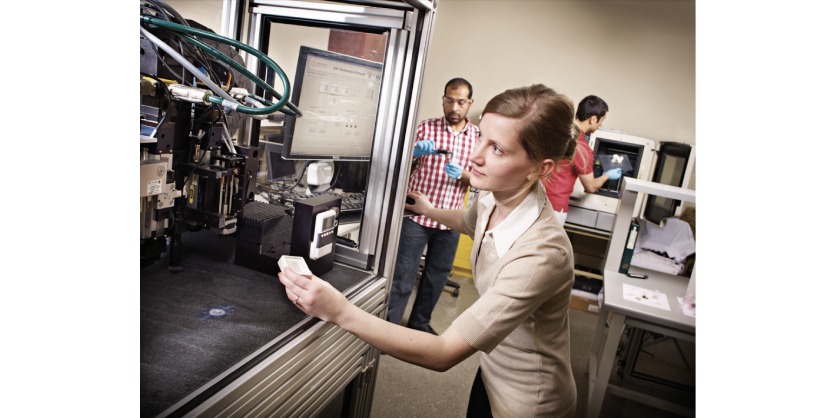

Waterloo’s MSAM Lab is increasing capacity for research, training and partnerships to meet growing demands in the field of advanced manufacturing

By Darren McAlmont, University Relations

In 2004, the Multi-Scale Additive Manufacturing (MSAM) Lab at the University of Waterloo was a small, 150 square foot, windowless space. Today, it has expanded to become the largest metal additive manufacturing (AM) academic research lab in Canada, with more than $25 million in infrastructure, and is one of the most comprehensive university-based metal AM facilities globally.

The expansion of the lab enables both industry and students to access top-tier expertise and equipment, facilitating the comprehensive development, iteration and validation of additively manufactured products from raw materials to finished goods by applying advanced scientific discoveries to industrial contexts.

The research conducted by MSAM is shaping the future by working with industry, institutions and communities. These partnerships infuse research solutions into sectors critical for economic growth and innovation by fostering collaborations with industry leaders and promoting technology transfer.

“The team at MSAM has strategically aimed for innovation while developing the next generation of metal AM technologies — another way of saying 3D printed products.” says Dr. Ehsan Toyserkani, a Waterloo engineering professor and founder of the MSAM Lab. “We excel in novel material adoption and development, as well as creating innovative quality assurance algorithms and software solutions to enhance the resilience and sustainability of part production.”

Reflecting on the success and growth of the lab over the years, Toyserkani shares that its early success began in 2005 through a collaboration with Mount Sinai Hospital at the University of Toronto and biomedical researchers from other universities. Across the span of six years, the collaboration resulted in a patented 3D printing technology for creating anatomically shaped implants from a novel biodegradable material called calcium polyphosphate.

“The MSAM Lab is developing technologies for the future,” says Dr. Mihaela Vlasea, Waterloo engineering professor and co-director of the MSAM Lab.

“It significantly transforms both large and small-scale advanced manufacturing while accelerating sustainability. The lab enhances clean technology and responsible production by adopting economically- and environmentally sustainable materials by minimizing waste through precise material deposition, which reduces excess consumption and energy use.”

With a new facility spanning approximately 15,000 square feet, the lab serves as a central hub for research teams and houses cutting-edge metal additive manufacturing printers and characterization devices. This expansion was partly funded by the approval of large equipment grants from the Federal Economic Development Agency for Southern Ontario, Canada Foundation for Innovation and the National Research Council. The larger, safer facility supports industry and fosters economic development by increasing capacity for research and development (R&D), validation, and technology transfers to meet growing demands in the AM field.

The facility has also attracted top research talent, strengthening Waterloo’s position on the global map for scholarly discoveries in additive manufacturing.

“By consolidating all critical devices under one roof, we streamline operations, encourage collaboration and prioritize safety,” Toyserkani shares. “The space also provides unique facilities for undergraduate and graduate students as well as a gateway for industry to explore AM technologies and collaborate together to mitigate R&D risks.”

More importantly, MSAM’s research significantly enhances Canada’s research capabilities, increases societal impact, and addresses complex global challenges through innovative solutions. This is evident from MSAM’s leadership role in a national strategic network called “Holistic Innovation in Additive Manufacturing” (HI-AM), which includes seven Tier 1 universities from coast-to-coast.

Businesses can leverage MSAM for a variety of additive manufacturing needs, including advanced prototyping and customization of products, including those not yet commercially available. The lab also provides training programs to cultivate a sustainable workforce of skilled advanced manufacturing professionals.

As Waterloo embraces additive manufacturing’s potential for innovative R&D through MSAM, it stands at the forefront of advancing custom-product development, providing intelligent quality assurance platforms and shaping the future of AM.

MSAM’s growth has created numerous employment opportunities and new R&D programs, attracting investments from the aerospace, automotive, energy and nuclear, natural resources and mining, and biomedical industries.

“Some post-graduate students who worked at MSAM as research associates and project managers have gone on to establish start-ups like Brickeye, OptiFab, and Formions,” Vlasea says. “Others have become professors at top universities in Canada and the United States or joined leading AM companies.”

As an expert on additive manufacturing processes in the aerospace industry, Vlasea delivered a talk on metal AM and case studies in aviation at the Waterloo Institute for Sustainable Aeronautics Summit on November 19, 2024 at Bingemans Conference Centre in Kitchener.

Looking ahead, MSAM’s mandate is focused on not only continuing the track record of scholarly excellence and R&D industry engagement, but also on developing new industry training programs, training more students, helping industry to adopt and scale AM and producing more patents and intellectual properties.