Solid State Relays with Diagnostics from celduc® relais

March 11, 2025

celduc® relais has developed a range of Solid State Relays (SSRs) with integrated diagnostics to improve real-time monitoring.

In order for machine builders to make informed decisions, solve urgent problems on short notice and develop machines that are more autonomous, data from the various components within the machine needs to be collected and analysed. celduc® relais has developed a range of Solid State Relays with diagnostic functionality that meet these requirements.

- To detect load failures, blown fuses, heat zones status, as well as damaged and interrupted SSRs

- Reduced unplanned downtime

- Predictive and better preventive maintenance plans

Applications

celduc’s range is suited for applications where monitoring of the field level devices is required to minimize expensive downtimes, such as :

- Plastic injection machines

- PET blow moulding machines

- Packaging machines

- Semiconductor manufacturing machinery

- Glass tempering machines

1-Single phase Solid State Relays with diagnostics

celduc’s SOD solid state relays incorporate monitoring functions for fast failure detection. Timely detection for mains loss, load loss, SSR open and short circuit are all possible with the SOD series. This range of solid state relays is equipped with an Alarm LED for visual indication of fault presence.

celduc’s SOD range is available from 35A to 125A – 50-265VAC or 150-510VAC. NC (Normally Closed) diagnostic contact.

If mains voltage is applied, the yellow LED is ON : the yellow LED means that the installation is working normally.

When the control is activated, the green LED is ON.

Here are the failure detection :

–Mains status : celduc’s SOD type relay detects a power outage, during a sudden voltage interruption for example.

–Load status : celduc’s SOD type relay allows you to know, in real time, the status of the load: connected or not. If the load is disconnected, the status output is opened and the yellow LED is off.

–Protection status : celduc’s SOD type relay also makes it possible to detect a breakdown in mains protection (with or without the control applied). If the mains protection has failed, the status output is opened and the yellow LED is off.

–SSR output status : It is also important to know the status of the relay output (closed or open). When the Solid State Relay is short-circuited, Diagnostic output is activated and yellow LED is off.

Compact, ready-to-use solution with integrated heatsink

celduc also offer a compact, ready-to-use solution with integrated heatsink : SILD range.

Advantages of the SOD / SILD ranges :

- Easy to use

- The diagnostic function does not require an external power supply

- Quick reaction time < 100 ms

- The potential-free diagnostic output contact allows different wiring configurations

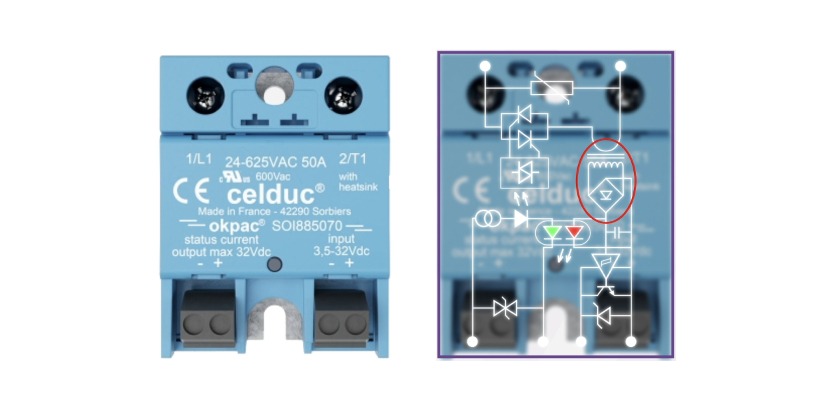

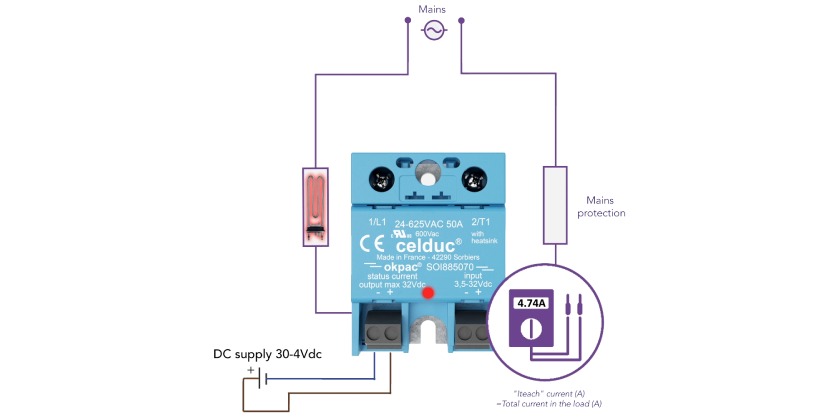

2- A New-concept SSR with Built-in Current Transformer

celduc’s SOI range has a built-in Current Transformer (CT) as well as a status output. This SSR makes it possible to switch the load current by providing information about the presence (or lack thereof) of the output current which must then be interpreted by the user or the system.

Normal operation : When the control is not activated, the LED is off. No current / Status output closed. When the control is activated, SOI type relay indicates that a current is flowing in the load.

Advantages of the SOI range : “Intelligent” SSR with Built-in current transformer

- This relay is ideal for detecting a load break and guaranteeing the best process quality.

- The built-in Current Transformer (CT) allows a reduction of quantity, cost and time of wiring.

- Current sensing is integrated inside to eliminate the need to install an external current transformer.

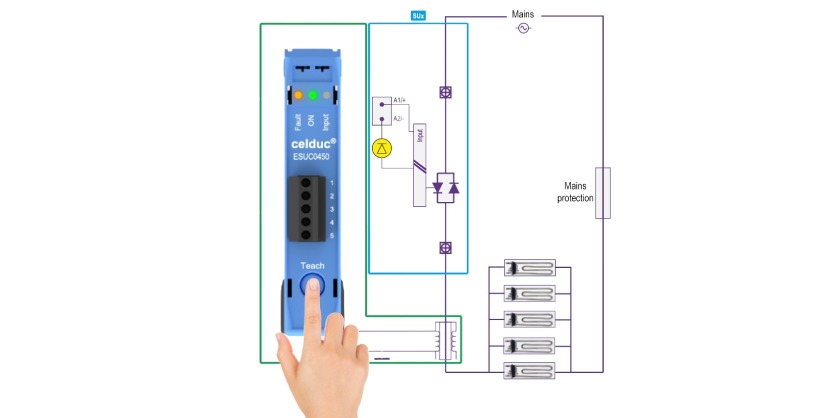

3- ESUC Module : Current monitoring module

ESUC module is directly pluggable onto celduc’s SU, SUL and SUM type SSRs.

Combined with celduc’s SU, SUL and SUM type SSRs, you can add diagnostics and control up to 5 heaters loads.

Advantages of the ESUC module :

- Quick fault detections (including partial load break detection)

- Real-time control of the correct operation of your installation

- Maintains good quality production for plastic/rubber machines

- With its 22.5 mm width, the space requirement is minimal

- Reduction of quantity, cost and time of wiring

- Three-phase or multi-zone use capability

4- ECOM MODULE : Temperature controller PID, current monitor and communication interface in one unit

ECOM module is directly pluggable onto our SU, SUL and SUM type SSRs and is a compact solution providing a PID temperature controller, current monitor and communication interface in one unit.

Advantages of the ECOM module :

- Communication interface : real-time monitoring via Modbus RTU protocol

- Diagnosis of load and relay status with alarm capability

- Current monitoring up to 50A with current transformer

- Temperature measurement, PID control and alarms

5- Three-phase Solid State Relays with diagnostics

celduc’s SMB8670910 has an auxiliary contact allowing the detection, in real time, of various conditions: the status of the load, status of the relay output and the network.

The status (static) output is normally closed in the absence of faults on the load or on the relay itself. In the event of a fault, the status output is open.

Normal operation :

When the control is not activated, LEDs are off. No current / Status output closed.

When the control is activated :

– Green LED indicates that the control is activated.

– Red LED is off which indicates that the installation is working normally.

Here are the failure detection :

-Mains status: celduc’s SMB8670910 detects a power outage, during a sudden voltage interruption for example.

-Load status: celduc’s SMB8670910 allows you to know, in real time, the status of the load: connected or not. If the load is experiencing a failure, the status output is opened and the red LED is on.

-SSR output status: It is also important to know the status of the relay output (closed or open). When the Solid State Relay is short-circuited, Diagnostic output is activated and red LED is on.

Advantages of our SMB8670910 :

- Easy to use

- The diagnostic function does not require an external power supply

- Quick reaction time < 100 ms

- The potential-free diagnostic output contact allows different wiring configurations

6- Do you need specific diagnostic solutions?

celduc’s Salespeople will work with their R&D team to develop an optimal solution in response to your specifications.

Here is an example :

In addition to external failures, this specific product can also detect internal faults of the relay. For example, a failure on the opto-coupler, thyristor or solder joints. In case of failure, the diagnostic output is activated and red LED is on.

celduc® offers you reliable and efficient solid state relays with integrated diagnostic functions.

Related Story

celduc Is Pleased to Launch Their New Product Catalogue

celduc is pleased to announce the launch of their new Product Guide, featuring their most up-to-date range of products.