A Guide to Mechatronics – Part 1: Introduction & Fundamentals

June 17, 2024

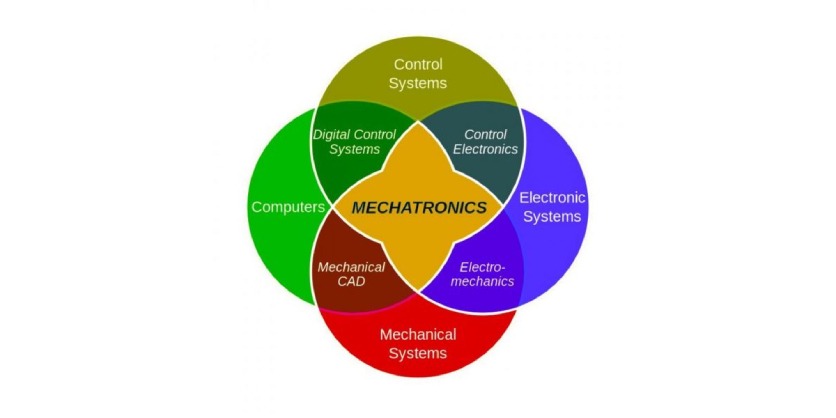

Mechatronics is a pivotal field that integrates mechanics, electronics, and computing, creating intelligent, adaptable, and versatile systems.

It combines mechanical engineering precision, electronic control, and computer decision-making to innovate products and solutions. This interdisciplinary approach represents a shift from traditional engineering to a holistic method, leveraging each field’s strengths for efficient and sophisticated systems.

Mechatronics is crucial in modern engineering, evident in robotic arms, medical devices, autonomous vehicles, drones, and advanced electronics.

The rise of IoT highlights its relevance, as it merges sensors, actuators, and communication technology. Mechatronics addresses pressing challenges like sustainable energy, advanced healthcare, and intelligent automation, optimizing systems for performance and efficiency.

This guide simplifies mechatronic subsystems for a broad audience, from students to professionals. It covers foundational aspects, demystifies sensors, actuators, and control systems, and emphasizes software’s role.

Practical applications in robotics, automotive, and healthcare industries demonstrate real-world impacts. Emerging trends and future directions are explored, aiming to inspire further innovation in mechatronics.

Section 1: Mechatronics Fundamentals

1a. Historical Context and Evolution

The journey of mechatronics as a field begins in the late 1960s, emerging as an intersection of mechanics and electronics.

The term ‘mechatronics’ itself was first coined by Tetsuro Mori, an engineer at Yaskawa Electric Corporation, to describe the integration of these disciplines in the development of industrial products. Initially, it was a marketing term for the seamless blend of ‘mechanical’ and ‘electronic’ engineering, but it quickly evolved into a recognized engineering discipline.

In its early stages, mechatronics was primarily focused on adding electronic control to mechanical systems, enhancing their functionality and precision.

The advent of microprocessors and advancements in digital electronics in the 1970s and 1980s propelled mechatronics into a new era. This period saw the introduction of more sophisticated control systems and feedback mechanisms, allowing for greater automation and precision in mechanical systems.

The 1990s and 2000s marked a period of rapid growth for mechatronics, fueled by leaps in computer technology and software. These advancements expanded the scope of mechatronics beyond traditional fields, incorporating elements of computer engineering, software development, and systems design. This era saw the birth of many modern mechatronic systems, such as advanced robotics, automated manufacturing processes, and intelligent vehicle systems.

Today, mechatronics stands at the forefront of technological innovation, integrating cutting-edge developments in artificial intelligence, machine learning, and the Internet of Things (IoT). It plays a critical role in developing smart systems and technologies that are reshaping industries, healthcare, and daily life.

The evolution of mechatronics is a testament to the power of interdisciplinary collaboration and innovation, constantly pushing the boundaries of what is possible in engineering and technology.

1b. Core Elements and Interdisciplinary Integration

Mechatronics is a synergistic blend of several engineering disciplines, each contributing crucial elements to the creation of sophisticated systems. Understanding these core elements and how they integrate is key to grasping the essence of mechatronics.

Mechanical Engineering: This is the backbone of mechatronics, providing the fundamental principles of motion, force, and energy. Mechanical elements like gears, levers, and cams form the physical structure of mechatronic systems. In mechatronics, these components are often miniaturized and optimized for efficiency and precision.

Electronic Engineering: Electronics bring intelligence to mechatronic systems. This involves the use of sensors to gather data, actuators to control movement, and electronic circuits to process signals. Microelectronics play a pivotal role, especially in miniaturizing control circuits and enhancing system performance.

Computer Science: The brain of a mechatronic system lies in its computing capability. Computer science contributes through software development and data processing. It enables the system to make decisions, process complex algorithms, and interface with other digital systems. Programming languages, software engineering principles, and data algorithms are vital components.

Control Engineering: This aspect deals with system behavior and response. Control engineering ensures that mechatronic systems perform desired tasks accurately and efficiently. It involves developing mathematical models to predict system behavior and designing control systems, often utilizing feedback loops for self-regulation and adaptation.

Systems Design: The integration of mechanical, electronic, and computing elements requires a holistic approach, which is where systems design comes in. It involves the architectural planning of the system, ensuring that all parts work together seamlessly. Systems design in mechatronics focuses on optimizing the interaction between different components for overall system effectiveness and reliability.

The interdisciplinary integration in mechatronics is not just about combining these elements but orchestrating them in a way that the strengths of each discipline are maximized. This integration leads to the creation of systems that are more efficient, versatile, and capable than the sum of their parts. It requires a deep understanding of each field and an appreciation of how they can complement and enhance each other in a cohesive system.

Stay tuned as we release more of our Introduction to Mechatronics series each week. Next week, we will be discussing the Composition of a Mechatronic Subsystem.

This article is original content created and posted by Electromate. Please do not re-post this content without prior approval from Electromate.

Related Story

Heavy Payload Cobots vs Traditional Robots for Industrial Automation

Adopting collaborative robots (cobots) represents a significant shift in automation strategies. Universal Robots is a frontrunner in the cobot sector and delivers solutions that are transforming industrial automation. This discussion provides detailed reasons why Universal Robots’ cobots are ideal for most industrial automation applications.