Rittal Automation Systems – Revolutionizing Enclosure Manufacturing

January 19, 2024

Elevate your enclosure production process with the cutting-edge solutions offered by Rittal Automation Systems. Representing a comprehensive suite of products and services, Rittal Automation Systems spans the spectrum from manual tools to state-of-the-art, fully automated machine technology tailored for enclosure manufacturing.

Experience accelerated, precise, and ergonomic machining and assembly of enclosures and components, addressing a myriad of tasks such as drilling, milling, laser cutting, bending, punching, population, and wiring. Rittal Automation Systems is your one-stop solution for unparalleled efficiency and performance.

Key Advantages of Rittal Automation Systems:

- Boosted Productivity and Efficiency: Slash machining and assembly time by up to 80% compared to conventional methods. Rittal’s Automation Systems offers high-performance, user-friendly machines and software, enhancing overall operational efficiency.

- Precision and Quality Excellence: Ensure consistent, error-free results with advanced technology and precision tools. Rittal’s Automation Systems handles a diverse range of machinable materials, including spray-finished sheet steel, stainless steel, aluminum, copper, and plastic.

- Safety and Ergonomics: Prioritize the well-being of your workforce with ergonomic, safe machine and tool designs. Integrated features such as dust extraction and noise reduction systems guarantee a clean and serene working environment, minimizing the risk of injuries and fatigue.

Discover More at Our Exclusive Webinar:

Uncover the transformative capabilities of Rittal Automation Systems by joining our upcoming webinar on January 24th at 2PM EST. Secure your spot by registering at Registration (gotowebinar.com). Don’t miss this opportunity to revolutionize your enclosure manufacturing processes and propel your business to new heights with Rittal Automation Systems.

Related Product

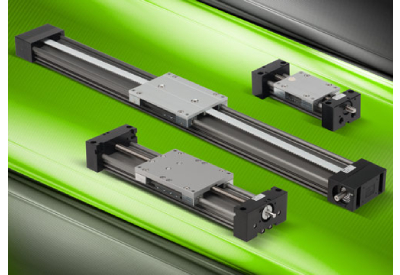

Perforex Milling Terminal MT – The Drilling and Milling Centres from Rittal Automation Systems

Automated solutions for mechanical machining? – Sure! Minimise process times with maximum precision. Our machines work quickly, precisely and highly efficiently. Benefit from the new features for your housing and flat part machining.