Spot at AB InBev Belgium | Boston Dynamics

January 10, 2024

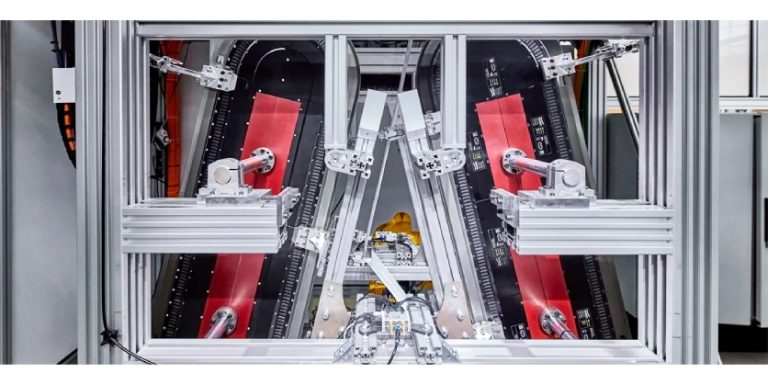

Spot at AB InBev Belgium

A key part of AB InBev’s “Brewery of the Future” program, Spot conducts 1,800 individual inspections each week across ten packaging lines that churn over 50,000 containers of Stella Artois, Budweiser, and Corona beer every hour. In the first six months of deployment, Spot discovered nearly 150 anomalies and slashed average repair times from a few months to 13 days.

More Information

Related Video

Spot at Ontario Power Generation

There are an estimated 30,000 instances of arc flash each year in the United States alone, and one to two fatalities occur daily in North America. Ontario Power Generation (OPG) has five Boston Dynamics’ Spot robots deployed throughout their Enterprise Innovation division.

Related Story

What’s New in Spot Release 3.3

Lights, Camera, Sensing! The industry standard for dangerous and routine autonomous inspections just got better, now with a brand new set of features and hardware.

Boston Dynamics announces brand new features and hardware for Spot, an industry standard for dangerous and routine autonomous inspections. Critical industrial tasks like thermal monitoring, acoustic leak detection, and gauge reading are made easier through our automated inspection solutions.