Swivellink Mounting Systems from AutomationDirect

May 3, 2023

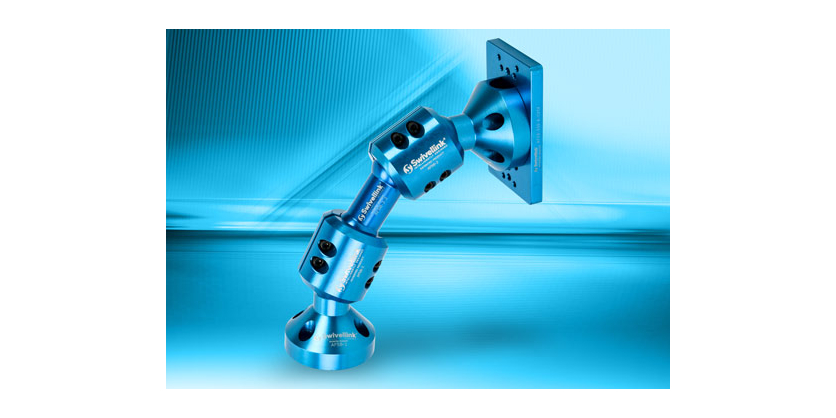

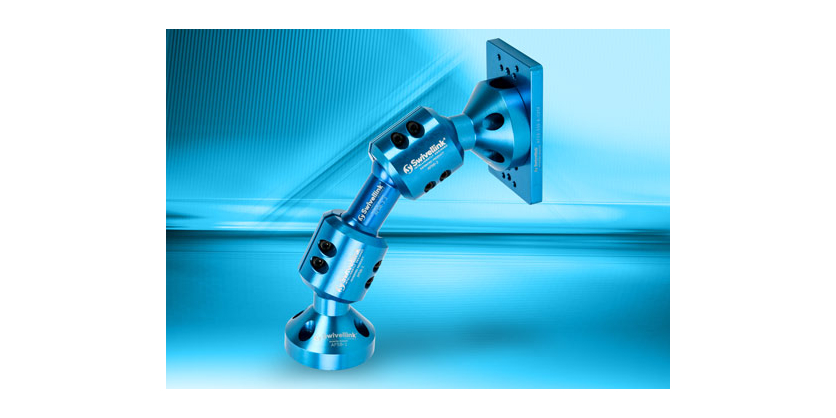

AutomationDirect has added Swivellink Standard series device mounting systems to their Barcode/RFID/Vision product category. Device mounting systems are assembled using several components and can be configured to mount vision cameras, lights, sensors, and scanners. They allow for precise adjustment and ease of equipment installation.

These mounting systems are modular, and components are selected individually to suit the needs of the application. The systems are custom configured and start with a base, which is fastened to the mounting surface. Then a link or tee is connected using knuckles which provide full rotational adjustment. Mounting plates finish the mounting system, predrilled for specific manufacturer equipment or blank for custom drilling.

Components are available in metric or imperial units and include bases, knuckles, links, tees, mounting plates, sensor mounts, and optional clamp handles.

Swivellink mounting components come with a one-year warranty and start at $19.00.

Device mounting systems for identification products are unique assemblies for mounting vision cameras, lights, sensors, and scanners. They allow for precise adjustment and ease of equipment installation. These systems are modular so all components are purchased separately.

The positioning of barcode scanners and vision components is an important part of product identification applications, especially with line-of-sight devices. Device mounting systems are modular products that allow precision mounting of vision cameras, lights, sensors, scanners and other devices. These mounting systems provide a convenient and easy method of installing those devices and adjusting their orientations as needed.

More Information

Related Product

Swivellink: What is the PLx?

The PLx family of safety validation devices are compact, hand-held devices that are designed to diagnose and induce faults in machinery safety systems to validate that the appropriate safety performance level has been achieved by the hardware design, manufacture, assembly, wiring, and programming of the system.