Identification and Access Management – I.A.M. from PILZ

November 7, 2022

How do you master the subjects of employee protection, liability protection, productivity and data protection? How do you increase your quality and simultaneously prevent tampering on your machines? How do you protect your data and employees in equal measure?

With “Identification and Access Management”, I.A.M. for short, we are offering a wide-ranging package of products and software, as well as tailor-made solutions for your daily access management challenges. We will help you organise your machine access and employee permissions. From simple authentication to complex access management, from functionally safe operating mode selection to electronic maintenance safeguarding. And also, of course, when protecting your valuable data from unauthorised access and from hacker attacks on your plant. With Pilz you’ll find the right solution and get safety and security in one system.

Work must be organised in such a way that hazards to physical and mental health are avoided. It’s something that should be a matter of course when operating industrial plant and machinery, but all too often is not given sufficient attention in practice, whether consciously or unconsciously.

For the best possible protection of your employees, you can have Pilz carry out a hazard assessment to check the hazard levels on your machines and examine how access must be secured. In addition to appropriate access permissions on safety gates and suitably qualified personnel, the use of operating modes is another adequate measure. Operating mode selection can be controlled with functional safety using PITmode products. This provides a technical guarantee that each employee can only carry out the work for which they are qualified, thus offering maximum protection against hazards and accidents.

Liability protection

If an industrial accident occurs, the immediate question is whether responsible parties can be made liable. For this reason, especially at company management level and among production and maintenance managers, it is essential that appropriate measures are taken, and that the effectiveness of these measures is checked on a regular basis. If this is neglected, employers and responsible parties can be held accountable for their actions, or for their failure to act!

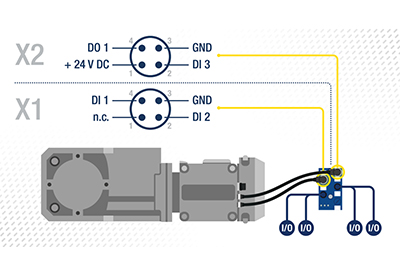

For example, potential measures are to select and train staff based on their tasks, and to provide them with the appropriate tools. In addition to organisational measures, you can also use technical solutions, such as access management with PITreader, for example. That way it is always possible to assign traceable, individual and if necessary temporary permissions for specific machines or processes.

Maintaining productivity

The necessary machinery safety measures must not be at the expense of your plants’ productivity. Machine downtimes – in the worst case with injured persons or damage to the machine – often happen as a result of tampering, incorrect operation or a lack of (access) controls. With clear responsibilities, relevant permissions and recording of user actions, you can prevent errors and provide optimum traceability. With its access management functions, PITreader offers an ideal solution for safety, security and maintaining the productivity of your valuable plant.

Data protection

Due to the constant changes in the standards situation, the focus is increasingly on data protection and network security. Comprehensive safety is no longer possible without also considering aspects of security. A holistic safety concept is required. In future, the Machinery Regulation, which comes into force in the EU in 2025, will take this into account.

However, your data, your know-how and your operations need protecting from unauthorised access today. Clever products such as the industrial firewall SecurityBridge, or even the switchable USB interface PIToe USB, offer security against “external” threats due to hacker attacks as well as threats “from within”, whether due to carelessness or intent. Use PITreader as an additional factor, so that all data connections can only be activated temporarily on site, as a result of deliberate operator action.

For further information, click here