Nidec Machine Tool Corporation Designs and Develops a New Linear Position Detector, Coming This Fall

April 5, 2022

Nidec Machine Tool Corporation (the “Company” or “Nidec Machine Tool”) recently announced that it has newly developed an “MPLW series,” an electromagnetic-induction-type linear position detector that digitally detects machines’ positioning, feed, and other information. While maintaining the resolution*1 and accuracy equal to those of the conventional model, MPLZ series, the MPLW series, which uses a newly developed signal detection method and a highly integrated substrates, has successfully eliminated the need of scale wiring and an analogue-digital converter (an “A/D converter”), and achieved a new, multiple-slider function and a low price. This new model will be launched in the machine tool and other industrial machine markets this fall.

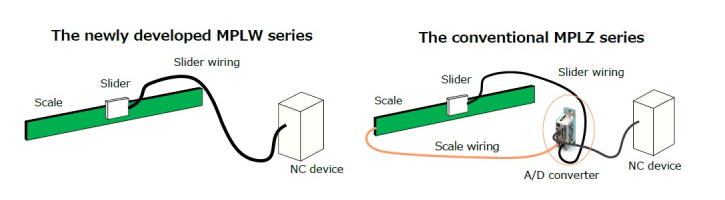

The MPLW series is a high-accuracy scale with a resolution of 0.01μm and a pitch accuracy*2 of 5μm, and it is used to detect the positions of general machinery’s linear axes. The conventional model, MPLZ series, would install a scale and a slider to a machine to connect a wire from the two, and transmit and receive electric signals with an NC (numerical control) device. However, the Company’s newly developed detection pattern, *3 which receives signals from a scale without mutual interference, has eliminated the need of scale wiring. In addition, to build inside the slider the function for an A/D converter to change electric signals from a scale into digital signals, the Company has developed a highly integrated substrate structure, enabling transmission and reception of signals with a machine’s control unit by using a scale and a slider only.

The development of these technologies has eliminated the need of using scale wiring and an A/D converter, reduced the number of required components, and shortened the manufacturing process, while significantly simplifying the installation work at our customers. Furthermore, the newly added function of installing multiple sliders into a single scale makes the MPLW series available for a wide variety of applications.

The electromagnetic induction method, the MPLW series’ most prominent feature, possesses excellent durability that keeps detection accuracy from being affected by dust, oil, or condensation. Combined with other characteristics such as long and stable accuracy maintenance and thermal resistance based on a complete non-contact structure, this method is supported by various fields of industry.

The Company stays committed to utilizing its machine tool-related technologies and the Nidec Group’s motor-related technologies and global network to advance the development of new products and meet the diversifying needs of its customers.

To learn more about the MPLW series from Nidec, click here