Lean Robotics: Making Robots Work in Your Factory

It was winter 2009, and Samuel Bouchard was on a mission to sell his startup’s first product, a robotic gripper, to the automotive manufacturers of Michigan.

It was winter 2009, and Samuel Bouchard was on a mission to sell his startup’s first product, a robotic gripper, to the automotive manufacturers of Michigan.

In the next ten years, more and more people around the world will be working with robots. Automation is becoming mainstream and is finding its way into more and more areas. Easy access to robotics:

Hawboldt Industries has installed an ABB winch drive with unique inbuilt active heave compensation (AHC) software at the heart of a new winch and offshore crane for the Research Vessel Kilo Moana.

“Innovative automation with a system.” For HandlingTech Automations-Systeme GmbH, the slogan says it all. Founded in 1994 as an automation newcomer in his parents’ basement turned parts business, Managing Director Jörg Hutzel’s family-owned company has developed into a veritable robotics player.

Speed and service are key to exceeding customer expectations, requiring more integrated practices, accessible intelligence and automated operations than ever before.

In the absence of a predictive maintenance strategy, manufacturers must take care of their equipment with regularly scheduled preventive maintenance. According to Plant Engineering, manufacturers spend an average of 19 hours per week maintaining their equipment.

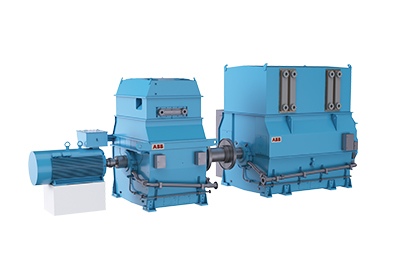

ABB has recently been awarded a major turnkey contract by Statkraft, Europe’s largest generator of renewable energy, to design, manufacture and install two high-inertia synchronous condenser systems for the Lister Drive Greener Grid project at Liverpool in Northwest England.

A project, supported by the German Federal Ministry of Education and Research, formed the basis for the research institute ICM e.V. to open a training and application center (“SchAz”) in Chemnitz.

Robotic implementation is becoming more prevalent in the Food & Beverage industry, especially in our current climate. And when focusing specifically on primary food handling (handling of raw, unpackaged food) there is an increased concentration regarding the utilization of robotics to maintain the hygienic demands of raw food handling.

Traditionally, many industrial companies have relied on their service providers to help keep their operations running profitably, safely, and reliably. The need for this relationship remains, but the challenge is how to perform service and maintenance duties amid current and future lockdowns, travel restrictions, and social distancing.

From electronics manufacturing to automotive assembly, grippers have become an important part of material handling processes in many industries. Their recent growth is tied to the rise of robotics—including the need for robots to take on specialty tasks and handle increasingly complex workpieces.

Some ten billion bearings are manufactured each year and, given the harsh conditions to which they are often subjected, they are incredibly reliable. Indeed, approximately 90% of these bearings outlive the equipment to which they are fitted.

Sulzer has used a fiber-optic sensing system from SKF to verify the design of a new centrifugal process pump. The sensing system measures loads directly in the bearing, which gives a deeper insight into a pump’s actual operating conditions.

Before diving deep into air dryers, it’s important to understand the components involved in an industrial air system. Air dryers are one of many elements that comprise the installation even before providing key airflow to your numerous machines.

A local equipment repair facility was facing a huge problem which was costing them thousands of dollars in repairs to their own equipment and delaying projects: water in their pneumatic airlines. Fortunately for them, there was a simple solution at hand. This repair facility made use of a many pneumatic-powered air tools and machines.

In its simplest form a pneumatic system uses compressed air to complete work. It starts with a compressed air source which is most often a compressor. A typical compressor will convert electrical energy to potential energy in the form of compressed air. It is this potential energy that is stored and distributed through the air lines for a variety of purposes.